EVOO in the Making | Pour More

What makes EVOO the best oil? The way it’s made, for starters.

We’ve all heard the experts weigh in. Certified EVOO wins, hands down, in any discussion of healthy oils and fats. Still, it’s not just the body benefits which keep us coming back — EVOO’s amazing flavor profile and wide range of uses easily make it the best choice from the market shelf.

But what makes EVOO so different from other oils? The way it’s made, for starters.

EVOO undergoes minimal processing — it’s as close to nature as we can get, and the highest in quality of all olive oils available to consumers. In both nutrition and flavor, it exceeds all other cooking oils produced — without the use of industrial refining or chemical processing. Even pure, light, and extra light olive oils can’t stake this claim!

To become certified EVOO, fruit must be harvested fresh and at the perfect time, so the olives themselves are healthy and juicy. The olives must be crushed within hours, and the juice extracted entirely by mechanical means, with careful attention to temperature. Temperatures above the threshold for EVOO certification degrade the oil, reducing both flavor and vital nutrients.

From start to finish, the process of making EVOO follows several important steps:

The harvested olives are prepared. On the day of harvest, the olive fruits are brought to mill as quickly as possible. They are sifted carefully through screens, removing any leaves, twigs, or debris. They are then rinsed, to remove any residues which might alter their fresh flavor.

The fruits are milled, or pressed. The freshly prepared olives are channeled into a mill, in which they are crushed to form a paste. Though the type of mill might vary (some use millstones or blades to grind, while others use hammer-like crushers), this process is performed without raising the temperature of the olives or their pulp.

While much of the oil is removed from the olives in this first step, the paste formed in this process is still rich with juice and oil.

The olive paste is mixed and agitated. Consisting mostly of olive pulp, skins, and crushed pits, the paste created is still rich with oils and health-giving polyphenols. Malaxation (agitation through a specially-designed machine) helps release liquids from the remaining solids, and allows oils to gather in larger droplets.

Oil is pressed from the olive paste. Pressing removes additional liquids from the pulpy, malaxed paste. The resulting extract is a mixture of oil and water, which must then be separated in order to create high-quality EVOO.

All water is removed. The extracted oils are fed through a centrifuge, which rotates at top speeds. Because water and olive oil are of different densities, the spinning motion of the centrifuge separates the two substances quite effectively. The remaining oil is now free of water, and ready for clarification.

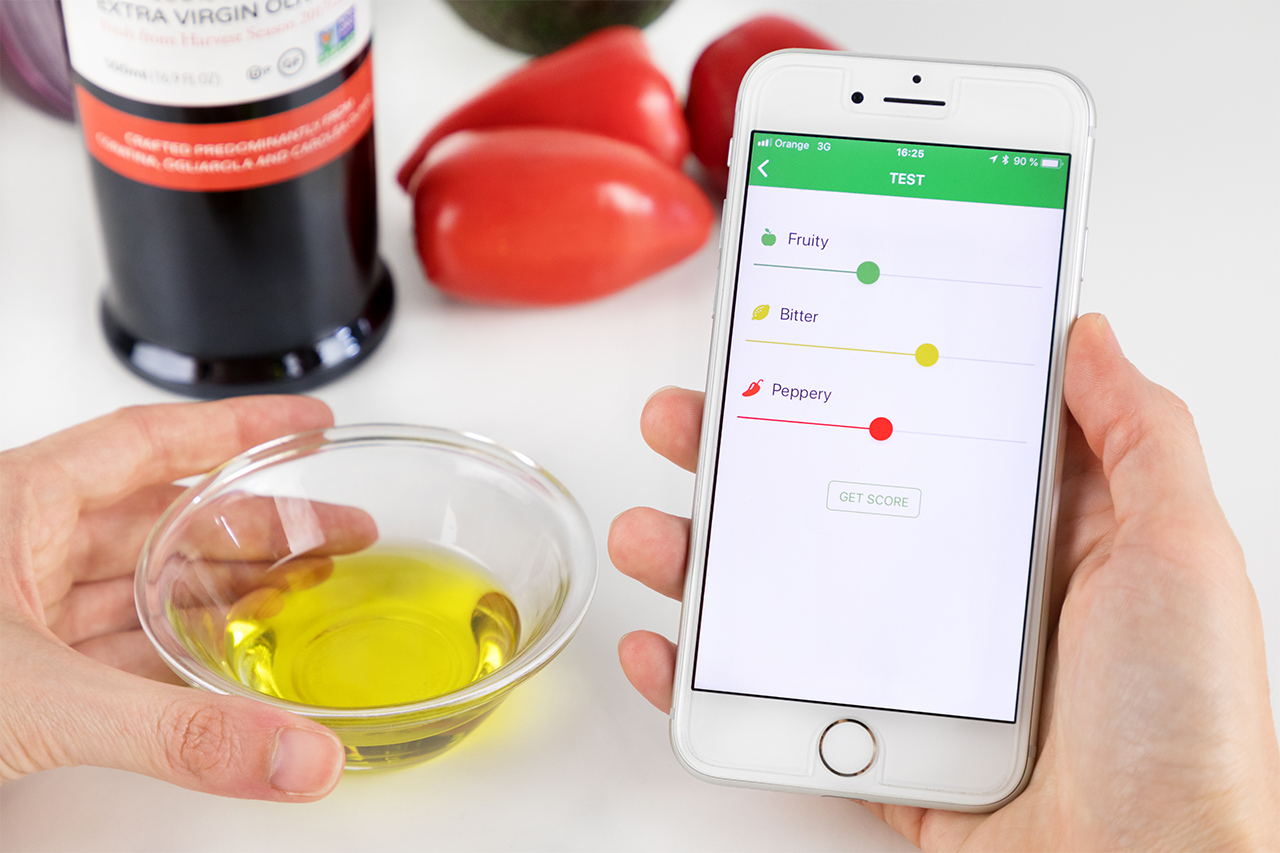

Acidity levels are tested. According to standards outlined by the European Commission, in order to be labeled Extra Virgin, olive oil must feature a free acidity lower than 0.8%. Higher acidity indicates lipolysis, a deterioration of the olive fruit. Though lipolysis can be caused by many things - exposure to microorganisms, mold, contamination, pests, or simply a delay in harvest or processing - the presence of high levels of free fatty acids ultimately means the olives used were unhealthy, resulting in a lower-quality oil.

Low free acidity is a defining characteristic of high-quality EVOO - which is why rigorous testing is a must for all Bellucci products.

Fresh oil is filtered for bottling. Like fine wine, this batch of fresh EVOO is allowed to rest briefly, in order to filter out any sediments or impurities prior to bottling. Temperatures are controlled and constant, in order to prevent deterioration of nutrition and flavor profiles.

Making EVOO from freshly harvested oil requires a validation process. Making EVOO isn’t easy! The designation of Extra Virgin is not easy to obtain — and strict standards for taste and preparation mean most olive oil won’t make the cut. Those that do become Extra Virgin Olive Oils (like Bellucci!) will be proud to say so right on the label. Why wouldn’t they?

EVOO have proven themselves to have fresh and verdant flavor, to be free of defects, and to have undergone verification which considers the entire journey from fruit to bottle, in order to ensure quality. That’s what makes high-quality EVOO — and high-quality EVOO is what sets us apart.

At Bellucci, we’re proud to be different — and you can taste it in every drop. Pour more!